Hazardous Location Lighting

Hazardous Location Lighting

Hazardous location lighting, sometimes called explosion proof lighting, is engineered to prevent the ignition of explosive gasses, vapors, or dust in hazardous environments. These fixtures use robust materials and sealed enclosures to contain possible sparks or flames, ensuring safety in industries such as oil and gas, chemical processing, and manufacturing.

Key Features of Hazardous Location Lights

- Durable Casing: Explosion-proof fixtures feature tough shells made of materials like aluminum, stainless steel, or fiberglass. These enclosures, along with shatterproof tempered glass lenses, protect against corrosion, impact, and explosions, preventing the ignition of flammable substances.

- Ignition Resistance: These fixtures use vapor tight seals to block the entry of flammable substances, ensuring safe operation even in environments with hazardous vapors or gases.

- Thermal Control Mechanisms: To help maintain safe temperatures and minimize fire risk, these lights incorporate heat-dissipating features like copper-free housings and aluminum heat sinks.

Types of Hazardous Location LED Lights

Explosion Proof High Bay

Suitable for high ceilings, these lights offer durable construction to withstand corrosive environments. They are common in oil refineries, chemical plants, and industrial facilities.

Explosion Proof Low Bay

Designed for spaces with ceilings under 20 feet, these fixtures provide efficient, focused lighting for confined work areas. They are used in locations such as storage rooms and loading docks where chemicals or vapors are present.

Explosion Proof Flood Light

Built to illuminate large outdoor spaces, these fixtures are ideal for oil rigs, fuel stations, and mining operations. They are designed to function in extreme temperatures while providing wide beam coverage.

Explosion Proof Emergency Lights

Essential for emergency scenarios, these lights automatically activate during power outages to ensure safe evacuation in hazardous areas like chemical plants. They include battery backup systems and durable enclosures.

Lighting Classifications for Hazardous Locations

The National Electrical Code (NEC) classifies hazardous environments based on the presence of flammable substances, defining safety standards for lighting fixtures to prevent fires or explosions.

Classification Systems for Hazardous Areas

Classes, Divisions, and Zones

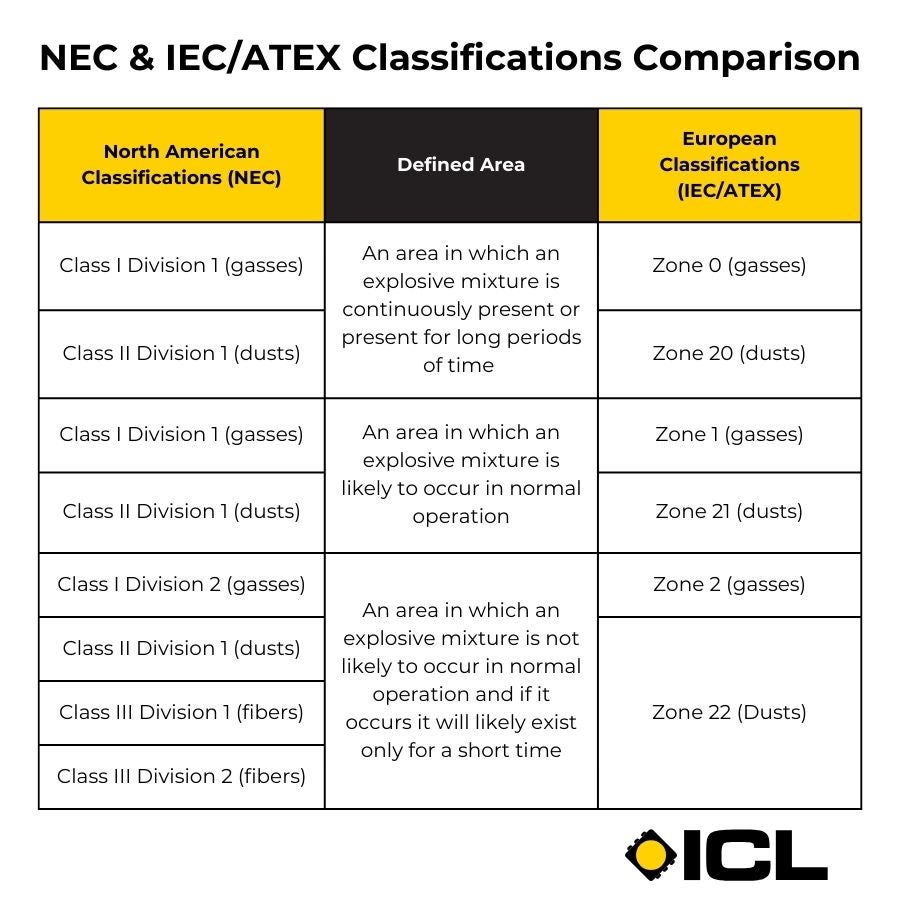

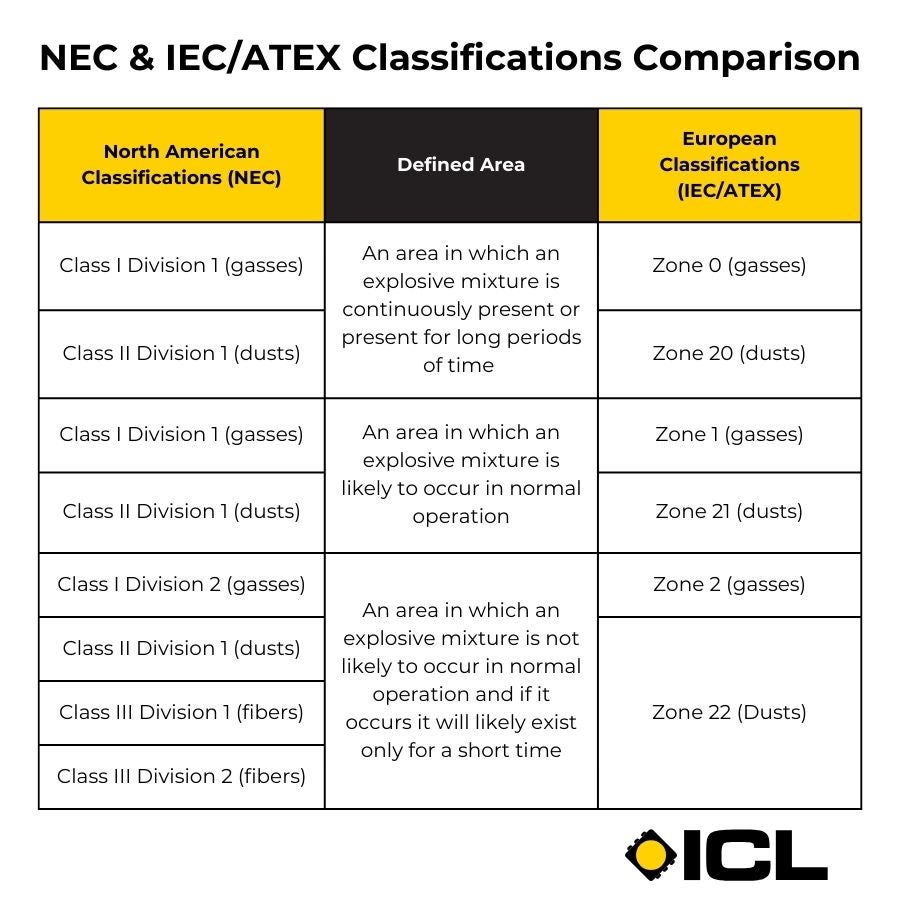

The NEC categorizes areas using two main systems:

Classes and Divisions (Article 500)

- Class I, Division 1: Explosive gasses/vapors are present during normal operations.

- Class I, Division 2: Such gasses/vapors may exist only under abnormal conditions.

- Class II, Division 1: Combustible dust is present during normal conditions.

- Class II, Division 2: Dust is typically absent during normal operations.

- Class III, Division 1: Nonmetal fibers/flyings are present under normal conditions.

- Class III, Division 2: These materials are stored or handled, not actively manufactured.

Zones (Articles 505 and 506)

- Zones 0, 1, 2: For gasses/vapors ranging from continuous (Zone 0) to rare exposure (Zone 2).

- Zones 20, 21, 22: Dusts and fibers are classified similarly based on exposure frequency from continuous (Zone 20) to rare exposure (Zone 22).

Temperature Classification (T-Classes)

Temperature classifications indicate the maximum surface temperature of equipment under standard conditions (40°C or 104°F). These classifications ensure equipment remains below the ignition point of hazardous materials. Examples include:

- T1 Class: 450°C (842°F)

- T2 Class: 300°C (572°F)

- T3 Class: 200°C (392°F)

- T4 Class: 135°C (275°F)

- T5 Class: 100°C (212°F)

- T6 Class: 85°C (185°F)

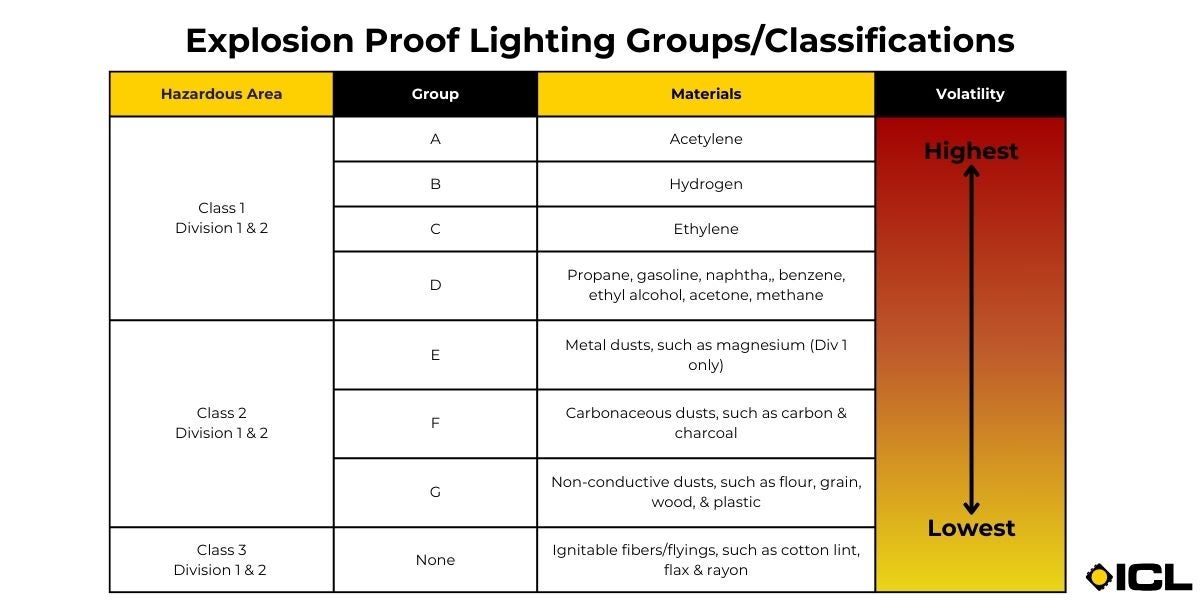

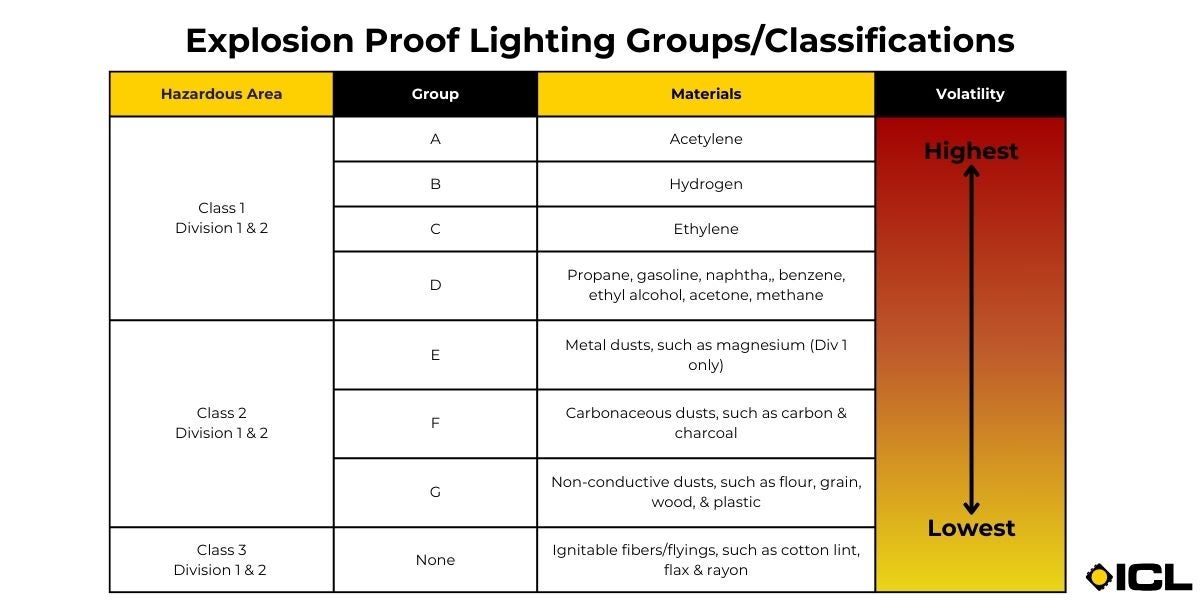

Hazardous Location Groups

The Occupational Safety and Health Administration (OSHA) further classifies hazardous locations into groups based on the properties of substances:

- Class I Groups A-D: For gasses like acetylene (A), hydrogen (B), ethylene (C), and propane (D).

- Class II Groups E-G: For dusts including metal dusts (E), carbon dusts (F), and non-conductive dusts like wood or grain (G).

Key Certifications for Hazardous Location Lighting

When choosing LED lighting for hazardous areas, it is crucial to look for certifications demonstrating compliance with industry standards.

Key certifications include:

-

UL (Underwriters Laboratories): Certifies products for safety and performance in hazardous locations in North America.

-

CSA (Canadian Standards Association): Provides certification for safety compliance in Canadian markets.

-

IECEx (International Electrotechnical Commission System for Certification to Standards Relating to Equipment for Use in Explosive Atmospheres): A global certification system for ensuring that products meet IEC standards for hazardous locations.

-

ATEX (Atmosphères Explosibles): The European Union’s certification directive that indicates compliance with safety standards for equipment used in explosive atmospheres.

Explosion-proof lights must be certified to match the specific class, division, group, or zone where they will be installed, ensuring safe and compliant operation.