Introduction

LED high bay lights are essential for illuminating large spaces with tall ceilings, such as warehouses, manufacturing plants, gymnasiums, large shopping centers, airplane hangars, and shipping facilities. This article will explore the different types of LED high bays.

We'll also cover key factors to consider when selecting LED high bays, such as the space's purpose, appropriate wattage and lumen output, spacing, and mounting options. You can make an informed decision based on each high bay's benefits and optional advanced features, such as sensor-ready and network-controlled high bays.

What Are High Bay LED Lights?

High bay LED lights are a type of lighting fixture designed specifically for spaces with high ceilings, typically 20-45 feet from the floor. These lights provide powerful, efficient illumination over large areas, making them ideal for industrial and commercial environments such as warehouses, factories, gymnasiums, and big-box retail stores.

LED technology in high bay lights offers advantages like energy efficiency, long lifespan, and reduced maintenance compared to traditional lighting options, making them a popular choice for facilities looking to improve lighting quality while lowering operational costs.

Types of LED High Bays

There are several types of LED high bay lights, each designed for specific applications and environments:

UFO High Bays

Named for their round shape, UFO high bays are compact and highly efficient. They are ideal for general-purpose lighting in warehouses, factories, and large indoor spaces. Their wide beam angle helps distribute light evenly across large areas.

Linear High Bays

These rectangular lights are designed to replace traditional fluorescent tube lighting in large, open spaces. They are commonly used in settings like gymnasiums, supermarkets, and large retail stores, where broad light distribution is needed.

NSF Washdown High Bays

Specifically designed for environments that require strict hygiene standards, such as food processing plants and pharmaceutical facilities, these high bays are built to withstand regular washdowns and exposure to moisture and chemicals. They also meet the lighting requirements for NSF (National Sanitation Foundation) standards.

High-Temperature High Bays

These high bays are engineered to perform in environments with extreme heat, such as factories, steel mills, and other heavy industrial settings. They are built with heat-resistant components to ensure reliability and longevity even in challenging conditions.

Sensor-Ready High Bays

These high bays are equipped with technology that can integrate motion and daylight sensors, allowing for automated lighting control. This feature enhances energy efficiency by ensuring the lights operate only when needed, making them ideal for spaces where occupancy varies or natural light is present.

Where to Use LED High Bays

LED high bays are ideal for spaces with tall ceilings, typically 20 feet or higher, requiring powerful and efficient lighting. They are commonly used in large industrial and commercial environments, such as warehouses, manufacturing plants, and distribution centers, where uniform and bright illumination is essential for safety and productivity.

These lights are also well-suited for facilities with high ceilings, like gymnasiums, large retail stores, and airport hangars, where consistent lighting over wide areas is necessary. LED high bays excel in spaces where traditional lighting would struggle to provide adequate illumination or would result in higher energy costs.

Additionally, LED high bays are often used in specialized environments like cold storage facilities, where temperature stability is crucial, and in areas requiring hygienic lighting solutions, such as food processing plants. Their versatility and efficiency make them the preferred choice for various applications.

Factors to Consider When Selecting High Bays

The Space’s Purpose

The intended use of the space plays a critical role in determining the type and number of high bay lights required. For instance:

- Warehouses: Bright, widespread lighting is required to ensure visibility across large, open areas. High lumen output and wider beam angles are ideal for effectively covering vast spaces.

- Gymnasiums: Bright, even lighting is required for safety and visibility in spaces like sports courts, gymnasiums, and weight rooms.

Spacing of High Bay Lights: How Many LED High Bay Lights Do I Need?:

Proper spacing of high bay lights is a critical aspect of lighting design in commercial and industrial spaces. The goal is to ensure consistent and adequate illumination across the entire area while optimizing energy efficiency and minimizing costs.

Several factors must be considered when determining the spacing of high bay lights, including the height of the ceiling, the beam angle of the fixtures, the lumen output, and the space's specific lighting requirements. If very specific lighting is needed, ICL provides IES files to help you determine what lights meet the facility’s needs.

Lighting Requirements of the Space

The space's lighting requirements play a crucial role in determining the optimal spacing of high bay lights. Different spaces have different lighting requirements based on their function and the activities that take place within them.

- Task-Specific Areas: In areas where precise tasks are performed, such as manufacturing floors or assembly lines, higher light levels are often required. In these situations, fixtures must be spaced closer together to provide sufficient illumination for detailed work. For example, in a manufacturing area, high bay lights may need to be spaced 10-15 feet apart to ensure that every workstation is well-lit.

- General Ambient Lighting: Storage or general walkway spaces have less demanding lighting requirements. Fixtures can be spaced further apart in these areas, as the primary goal is to ensure general visibility rather than focused task lighting. For example, spacing 20-30 feet between fixtures in a warehouse storage area may be sufficient to provide adequate ambient light.

Adjusting the spacing of high bay lights to match the space's lighting requirements ensures that the environment is both functional and energy-efficient. It also helps create a comfortable and safe workspace tailored to the facility's specific needs.

Ceiling Height

The height of the ceiling plays a crucial role in determining the spacing of LED high bay lights. It determines how far the light can travel before it reaches the ground and how far the light spreads out. As ceiling height increases, light disperses over a larger area and fixtures can be spaced farther apart. However, the fixture wattage should also be increased as ceiling height increases, and the lights are spaced further apart. Since light intensity diminishes as it spreads, higher wattage fixtures are needed to compensate for the reduced brightness.

- Low Ceilings (15-20 feet): In areas with relatively low ceilings, closer spacing between fixtures is necessary to ensure even light distribution and avoid shadows. Typically, spacing between 12 to 15 feet is recommended. This ensures that the light from each fixture overlaps sufficiently with adjacent fixtures, providing uniform illumination.

- Medium Ceilings (20-30 feet): The spacing between fixtures can be extended as the ceiling height increases. For ceilings in the 20-30 foot range, spacing between 15 to 20 feet is generally effective. This allows the light to spread out more while still maintaining adequate overlap between fixtures.

- High Ceilings (30-40 feet): In spaces with very high ceilings the spacing between fixtures can be increased to 20-30 feet or more. The light spreads widely at these heights, covering larger areas and reducing the fixtures needed to achieve uniform lighting.

The appropriate spacing ensures that the space is adequately lit while optimizing the number of fixtures used. This balance helps to reduce energy consumption and lower installation and maintenance costs.

Beam Angle

The beam angle of high bay light fixtures plays a role in determining how light is distributed across the space. The beam angle of a light source refers to the angle at which light is emitted, measured from the center of the beam to where the intensity drops to 50% of its maximum. In simpler terms, it indicates how wide or narrow the spread of light is from a fixture.

- Wide Beam Angles (e.g., 120°): Wide beam angles are ideal for spaces requiring broad, even coverage, such as open warehouse floors or gymnasiums. The wider light spread allows for greater spacing between fixtures, reducing the number of lights needed. For example, with a 120° beam angle, fixtures can often be spaced 20-30 feet apart in a high-ceiling environment while still providing adequate illumination.

- Narrow Beam Angles (e.g., 60°): Narrow beam angles focus the light more directly below the fixture, making them suitable for areas where concentrated lighting is needed, such as assembly lines or areas with tall shelving or areas with lower ceilings. In these cases, the fixtures must be spaced closer together, often between 10-15 feet apart, to ensure that the light covers the entire area without leaving dark spots.

Selecting the appropriate beam angle is crucial for achieving the desired lighting effect in different parts of the facility. It ensures that the lighting is effective and efficient, tailored to the space's specific needs.

Fixture Output (Lumens)

Lumen output, or the amount of light emitted by a fixture, directly impacts the spacing of high bay lights. Higher lumen output allows fixtures to be spaced further apart while still delivering sufficient illumination across the space. Conversely, lower lumen output requires fixtures to be placed closer together to maintain the same level of light.

- High Lumen Output (15,000-30,000 lumens): Fixtures with high lumen output are ideal for large, open spaces with high ceilings. These fixtures can be spaced further apart, often up to 25-30 feet, without compromising the uniformity of the lighting. This is particularly beneficial in environments where reducing the number of fixtures can lead to significant cost savings in both installation and energy consumption.

- Lower Lumen Output (10,000-15,000 lumens): Fixtures with lower lumen output are more suitable for spaces with lower ceilings or where more focused lighting is required. These fixtures need to be spaced closer together, typically 12-15 feet apart, to ensure that the space is evenly lit and that there are no areas with insufficient lighting.

Considering the lumen output when planning the layout of high bay lights ensures that the space is adequately lit while maintaining energy efficiency. It also allows for flexibility in lighting design, accommodating different levels of brightness in various areas of the facility.

Overlap and Uniformity

Achieving uniform lighting is essential in many commercial and industrial settings, particularly in environments where consistent illumination is critical. Proper spacing of high bay lights is key to ensuring that the light from each fixture overlaps slightly with the adjacent fixtures, creating a seamless lighting pattern.

- Overlap: The degree of overlap needed depends on the ceiling height, beam angle, and lumen output of the fixtures. Proper overlap helps to prevent dark spots or areas of uneven illumination, which can be problematic in spaces where consistent lighting is required, such as inspection areas or production lines.

- Uniformity: Uniform lighting ensures that the entire space is evenly lit, providing a safe and productive environment. This is particularly important in areas where visual tasks are performed, as uneven lighting can lead to eye strain or reduced efficiency. Proper spacing of high bay lights, with adequate overlap, is essential to achieving uniformity.

Planning for overlap and uniformity in the spacing of high bay lights helps create a well-lit environment that supports the space's needs. It ensures that the lighting is consistent and reliable, contributing to the facility's overall functionality and safety. This planning requires IES files which are provided for all of our LED high bay light fixtures.

Selecting Wattage for LED High Bays

When selecting wattage for LED high bays, it's important to consider comparable wattages to other types of lighting technologies. LED lights are more energy-efficient, providing the same or greater lumen output at a lower wattage. For example:

- Metal Halide: A 400-watt metal halide high bay can often be replaced with a 150-200-watt LED fixture, offering similar or better illumination with significant energy savings.

- Fluorescent: Fluorescent high bays may require a higher wattage than their LED counterparts to achieve the same lumen output, making LED a more efficient choice.

Understanding wattage equivalencies helps in selecting LED high bay fixtures that provide the desired light output while reducing energy consumption.

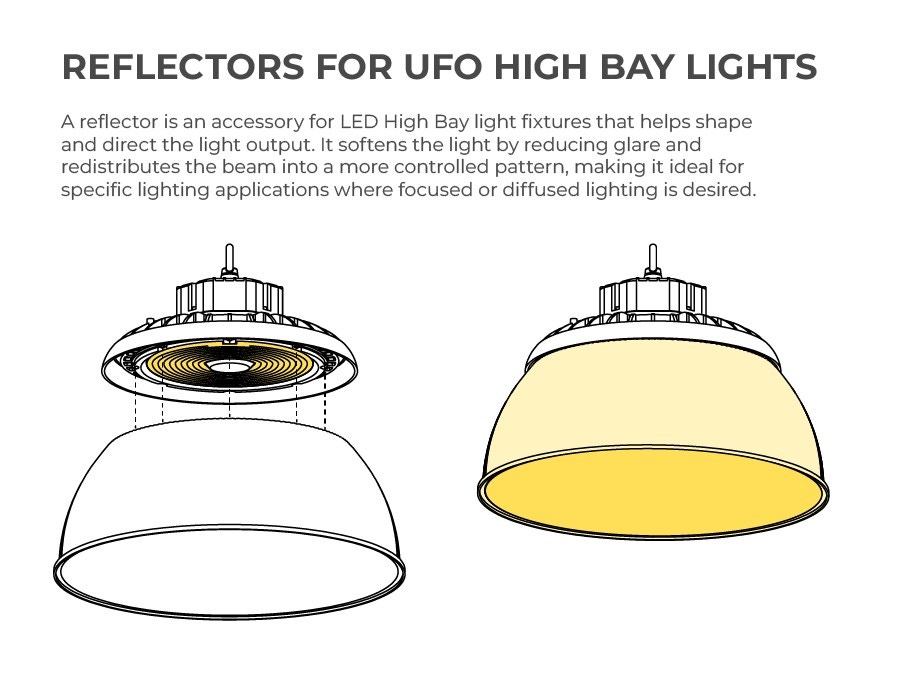

Why Use a Reflector on LED High Bays

Reflectors surround the light source of a high-bay fixture, almost like a lampshade, and help control the distribution of light emitted by the fixtures. The decision to use or not use a reflector on LED high-bay light fixtures depends on the desired lighting effect, the space's specific requirements, and the desired look.

A reflector on an LED high bay light helps control the beam angle, reduces light scatter, and enhances the concentration of light in certain areas. This is especially useful in spaces with high ceilings. It also gives an LED high bay light a traditional look compared to older lighting technologies. By directing the light downward, reflectors help improve overall illumination levels, reduce glare, and achieve more uniform light distribution in large industrial or commercial spaces.

Mounting Options with Purchase

Selecting the right mounting option is essential for effectively installing and operating LED high bay lights. Here are the common methods for mounting high bay lights:

Eye Bolts

Eye bolts provide a secure, simple way to hang high bay lights from chains or fixed points.

Easy installation, reliable attachment, and versatility across various environments.

Mounting Hooks

Hooks allow for quick, flexible suspension of lights, making adjustments easy.

Simple installation, height adjustability, and compatibility with different hanging systems.

V-Hook Suspension Kits

Kits include cables, chains, and other hardware for height control and mounting.

Precise positioning, stability, and a clean, professional look.

Choosing the Right High Bay Lights

By carefully assessing these factors, you can select the most appropriate mounting option for your LED high bay lights, ensuring optimal performance, safety, and aesthetic alignment with your space.

- Ceiling Height: Higher ceilings benefit from suspension kits; standard heights work well with eye bolts or hooks.

- Flexibility Needs: Choose hooks or suspension kits for adjustable setups and eye bolts for fixed installations.

- Aesthetic Importance: Suspension kits are best for visually sensitive environments, while eye bolts and hooks are best for industrial settings.

- Environment: Opt for durable options in harsh environments.

- Installation and Cost: Consider the ease and expense of installation when making your decision.

Networked Lighting Controlled High Bay Lights

Networked Lighting Controls (NLCs) are an advanced lighting solution that integrates LED high bay lights with smart technology. They enable enhanced control, energy efficiency, and flexibility in managing lighting systems. NLCs are particularly beneficial in large commercial and industrial spaces where precise lighting management is crucial.

Features of Networked Lighting Controlled High Bay Lights

- Centralized Control: Centralized control allows facility managers to adjust and monitor lighting across multiple fixtures from a single point, ideal for large spaces like warehouses. It saves time by eliminating the need for manual adjustments of individual fixtures.

- Automated Scheduling and Dimming: NLCs can automate lighting schedules and dimming based on occupancy or natural light, reducing energy usage and extending fixture lifespan. This contributes to operational cost savings and energy efficiency.

- Occupancy and Daylight Sensors: Occupancy sensors adjust lighting based on movement, while daylight sensors respond to natural light levels. These features ensure lights are used only when necessary and at the right brightness.

- Energy Monitoring and Reporting: NLCs provide real-time data on energy usage, allowing for detailed reporting and better decision-making to enhance energy efficiency and identify savings opportunities.

- Zoning and Grouping: NLCs enable the creation of lighting zones, allowing for customized lighting strategies in different facility areas. This increases energy efficiency by controlling groups of fixtures based on location or function.

- Remote Access and Control: Remote access lets facility managers control lighting systems from any location via smartphones or computers, allowing quick adjustments without being on-site.

- Scalability and Integration: NLC systems can scale with facility growth and integrate with building management systems for comprehensive control, improving overall efficiency and reducing operational costs.

By integrating advanced controls and automation, NLC systems enhance the functionality and efficiency of the lighting system and contribute to significant energy and cost savings. Whether for a large facility or multiple sites, NLCs provide the tools to optimize lighting and create a more sustainable and productive environment. For more information about NLCs, check out our blog "What Networked Lighting Controls Can Do For Your Business!"

Connect With a Commercial Account Representative

LED high bay lights offer a powerful, energy-efficient solution for illuminating large commercial and industrial spaces. With various types, including UFO, linear, NSF washdown, and high-temperature models, these fixtures are designed to meet the specific needs of diverse environments.

To learn more about how LED high bay lights can transform your facility and to explore available options, connect with one of our Commercial Account Representatives today to navigate your purchase and maximize your investment in energy-efficient lighting.